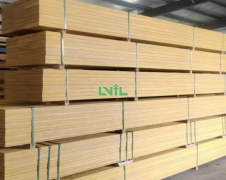

LVL Scaffolding Plank

LVL Scaffold Board

- Inquire Now

High Load-bearing Capacity: The LVL technology used in our scaffold boards provides an impressive load-bearing capacity, making them suitable for both light and heavy-duty usage. With strong dimensional stability and reliable thickness, the ...

Formply Plank is an engineered wood product designed specifically for use as a scaffold plank. It is created by permanently bonding individual veneers together, using adhesive, heat and pressure, with the grain in each layer of veneer running parallel to the grain in the next.The unique process by which it is manufactured disperses the inherent defects found in solid sawn lumber. Natural characteristics such as knots and wane are rearranged to maximize strength and minimize warping and split. Powered by Formply

www.formply.vn

www.formply.vn

Standards: OSHA (Standards & Regulations 29-CFR) 1926 Subpart L, Appendix A,BS 2482 Specification for Timber scaffold boards,AS1577-1993 Scaffold Planks Appendix A and Appendix B

https://www.formply.vn/

Core: Pine core and face https://www.formply.vn/

Adhesive: Phenolic adhesive for exterior use

RAINFOREST WOOD CO.,LTD.

Section Size: 38mm /42mmthickness and 225mm /230mm wide Copyright © RAINFOREST WOOD CO.,LTD. All Rights Reserved.

Moisture Content: Maximum 16% moisture

RAINFOREST WOOD CO.,LTD.

Lengths: 1.0 m to 6.0 m length range available www.formply.vn

End Sealant: Acrylic end sealant for additional moisture protection

www.formply.vn

Edge Branding: Permanent edge branding available at customer request Powered by Formply

Finish: Un-sanded faces, rounded edges, and painted ends https://www.formply.vn/

Standard Size

| thickness(mm) | width(mm) | length(m) | weight(kg/m) |

| 38 | 225 | 1.0-6.0 | 4.95 |

| 42 | 230 | 1.0-6.0 | 5.50 |

Formply

Formply

LVL Scaffold Board - the ultimate choice for construction and scaffolding projects. Crafted with precision using innovative Laminated Veneer Lumber (LVL) technology, our scaffold boards are designed to provide exceptional strength, durability, and safety on the job site. RAINFOREST WOOD CO.,LTD.

At Formply, we understand the importance of having reliable and sturdy scaffold boards that can withstand heavy loads and harsh conditions. Our LVL Scaffold Board is the result of extensive research and development, combining the best qualities of wood with the advanced engineering of LVL. Let's explore the features and benefits that make our scaffold board the top choice for professionals in the industry.

Formply

Formply

Strength and Durability: Built to last, our LVL Scaffold Board offers remarkable strength and durability. Constructed by bonding multiple layers of wood veneers, the resulting LVL board is stronger and more resistant to warping, splitting, and twisting compared to traditional solid wood boards. This stability ensures a safe and secure working platform for workers at varying heights.

High Load-bearing Capacity: The LVL technology used in our scaffold boards provides an impressive load-bearing capacity, making them suitable for both light and heavy-duty usage. With strong dimensional stability and reliable thickness, the boards can support heavy equipment, scaffolding structures, and workers with ease, without compromising on safety. Powered by Formply

Copyright © RAINFOREST WOOD CO.,LTD. All Rights Reserved.

Copyright © RAINFOREST WOOD CO.,LTD. All Rights Reserved.

Versatility: Our Lvl Scaffold Boards are designed to meet the diverse needs of construction and scaffolding projects. Available in different lengths, widths, and thicknesses, customers can select the most suitable size for their specific requirements. The boards are also compatible with various scaffolding systems and can be used horizontally or vertically, allowing complete flexibility during installation. RAINFOREST WOOD CO.,LTD.

Easy Handling: We understand the challenges workers face while transporting scaffold boards on-site. That's why our LVL Scaffold Boards are engineered to be lightweight without compromising their strength. This makes them easier to handle, reducing strain and fatigue on workers. Additionally, the boards are kiln-dried, ensuring stability and preventing excessive moisture absorption that can lead to weight gain.

www.formply.vn

Safety Measures: Safety is a top priority in any construction project, and our LVL Scaffold Boards have been designed with this in mind. Our boards undergo rigorous quality control tests to ensure they meet the highest safety standards, offering peace of mind to workers and project managers alike. With their superior strength and stability, the boards minimize the risk of accidents and provide a secure platform for scaffolding installations. Copyright © RAINFOREST WOOD CO.,LTD. All Rights Reserved.

Sustainability: We are committed to environmental sustainability and responsible sourcing. Our LVL Scaffold Boards are crafted from sustainably harvested wood and engineered with minimal waste in the manufacturing process. By choosing our LVL Scaffold Boards, you are contributing to a greener planet without compromising on performance or quality.

RAINFOREST WOOD CO.,LTD.

In conclusion, the LVL Scaffold Board is the epitome of strength, durability, and safety. Engineered with cutting-edge LVL technology, our scaffold boards offer excellent load-bearing capacity, versatility, ease of handling, and superior safety measures. With their industry-leading characteristics, these scaffold boards are a wise investment for any construction, renovation, or scaffolding project. Powered by Formply

Packing & Delivery

Company Profile

Formply is established in 2024. Its a branch of Formply which's professional manfacturer of Plywood and LVL in South of Vietnam more than 12 years. Our factory specialized in manufacturing plywood&LVL for contruction,furniture,commercial and packing. At present, we own 8 modern production lines which meet the technical and environmental standards. The capacity is about 2,000 cubes per month.Our main market is North America,Europe,Middle east,Africa,South East Asia and Australia.We supply commerical plywood,film faced plywood,fancy plywood,LVL Scaffold board,Structural LVL,Formwork LVL,LVL bed slat ,LVL door core and Packing LVL in these area.

For the past 12 years, we understand that the customer satisfaction is the key to success, the sustainable development for the company. Therefore, we always try our best to make plywood not only with good quality but also competitive price so that we can give the customer better than their expected. To do that, we strictly obey the production process.

We are always careful in selecting raw materials and checking the quality of plywood products. In addition, we always emphasize the role of workers, skilled and workers, who are highly responsible in work.

Thanks to endless efforts, now we become one of the biggest plywood exporters, especially the Asian market.

Located in the suburbs of Hanoi, only about 12 kilometers from the center of the capital, our factory is not far from the highway, airport. It's very convenient for transportation activities.

Welcome friends and clients visiting our factory and hope we soon expand business operation for the long lasting.

Please contact us for more information about products and the latest prices.

Navigation

News

Contact Us

Contacts: Lynn ng

Phone: +84 0795103121

Email: Linhtimber@gmail.com

Address: Lam Thao district, Phu Tho province, Vietnam